Tertiary Filtration and Polishing

Application of the filtration process depends upon the raw water quality and the end use of water. Depending upon the size and nature of the impurities the appropriate technique would be employed. A major design component is always efficiency of treatment and safe operation. Broadly tertiary filtration can be classified into dead-end and cross flow filtration. Within these modes there are various mediums employed according to each individual application and level of solids present in the water.

- Media Filtration

- Micro Filtration

- Ultra-Filtration

- Nano Filtration

- Reverse Osmosis

Image Credit: Canvas.jmu.edu & wcponline.com

Tertiary filtration can be deployed progressively beginning with media filtration carried out by sand or other specialized media filters. This at times can be enough to meet the water quality requirements of treated water. In case the particular reuse application requires a specific or better water quality, further polishing steps would be needed.

The science of filtration has kept pace with the overall dwindling clean water reserves. The sophistication and efficiencies of membranes have made tremendous strides to reduce the cost of treating water. For water scarce regions like the Middle East, desalination has become easier and more cost-effective.

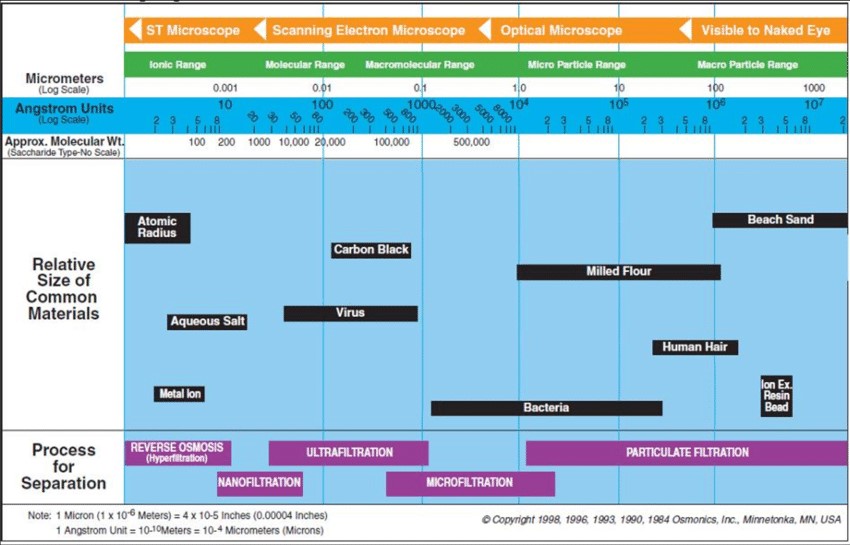

Membranes as part of tertiary treatment in effluent treatment plants have to provide enhanced water recoveries where reuse is a major project determinant. The overall process has to determine and then reduce the fouling potential of wastewater. Different means are employed according to each particular water quality and the task has become easier with various grades of available filtration options. Microfiltration, ultrafiltration, nanofiltration membranes are able to provide selective rejection of suspended and ionic dissolved solids.

Microfiltration achieves an effective barrier against suspended solids for the ensuing phases of membrane filtration and there are many choices available with different membrane manufacturers.

Ultrafiltration is a finer filtration stage which often can directly follow media filtration providing effective removal of pathogens, viruses and organics. The ultrafiltration stage is a critical design element and this more often than not the reason why systems fail, particularly when it’s not given due importance. In effluent treatment plants an ultrafiltration is a common precursor to reverse osmoses.

Nanofiltration has a certain specialized usage when it accompanies reverse osmosis or is present alone. In all cases it can remove divalent ions relevant to certain industrial and commercial applications. Care needs to be taken to realize its advantages with success.

Reverse osmosis membrane treatment suppliers are now differentiating themselves on the basis of higher recoveries and resilient systems. Selection and application of reverse osmosis process for optimum results requires an in-depth analysis of what can be the best viable treatment plant available within the now vast array of specializations.

In tertiary membrane treatment accurate design is very crucial otherwise it can lead to a very high OPEX and operation excursions. The customer is left saddled with maintenance downtimes, high consumption of cleaning chemicals and frequent replacement of RO membranes. It is very important to take into account all process eventualities and factor them properly in both the pre-treatment and main treatment zones.